The need for a better way to form helical screw flights is the driving force behind the development of AST’s patented TruHelix™ Helical Screw Flight Forming System.

The TruHelix™ Helical Screw Flight Forming System is exactly that: a system that encompasses both the intelligence of a proprietary software suite, and the tooling and machines that have been developed through the deep engineering knowledge of our highly experienced team of helical screw flight design and manufacturing experts.

In the past, the accuracy and consistency of the helical form – the true essence of the helix – was largely a function of the forming method, the experience of the operator, and the accuracy of the cut flight blank from which the helix was formed.

The TruHelix™ Helical Screw Flight Forming System has been designed specifically to provide consistent, accurate output, and high productivity, with minimal skill input from the operator. The system consists of the following components:

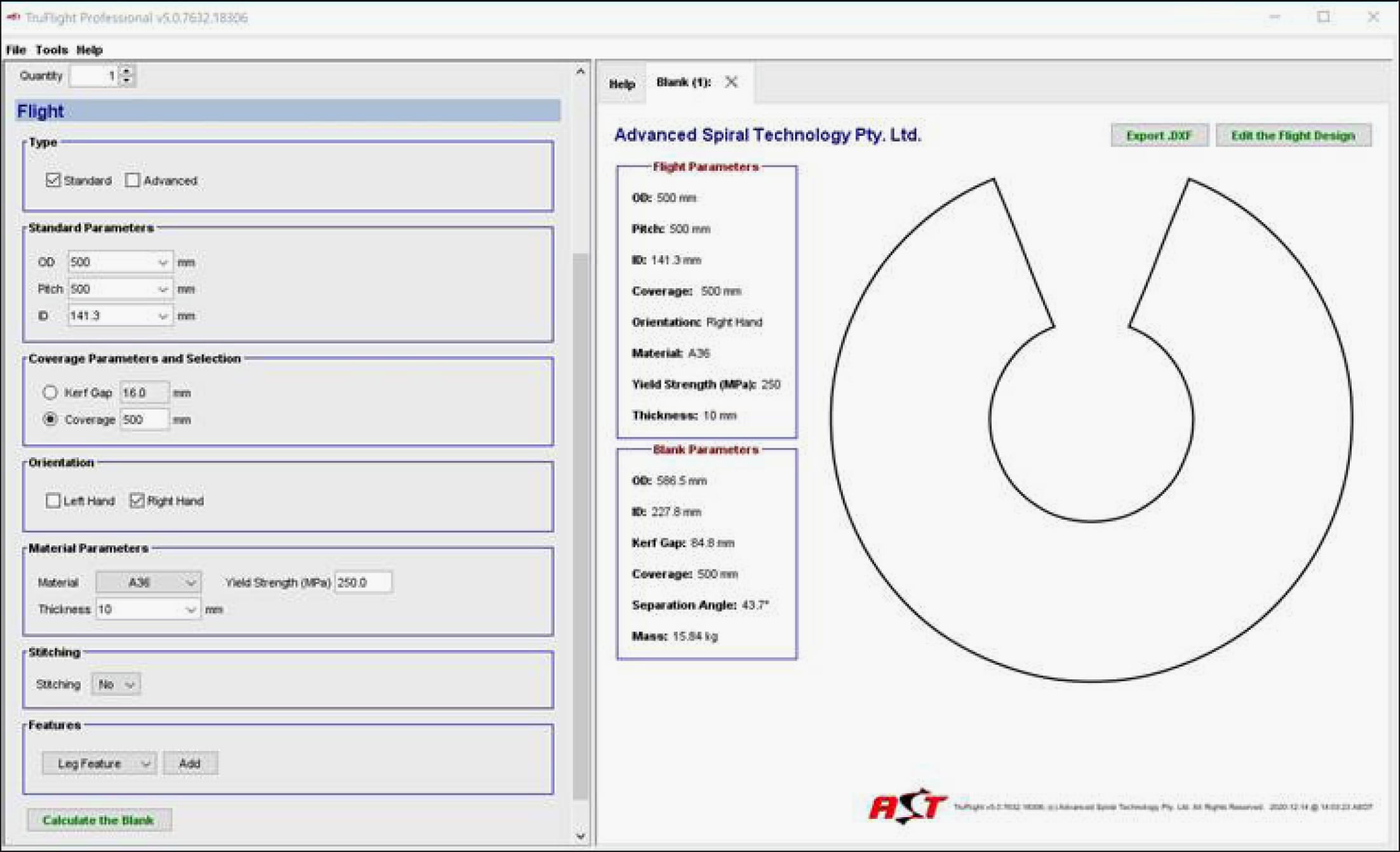

1. AST’s TruFlight™ Software Suite incorporates two unique modules that encapsulates the knowledge & expertise of helical screw flight manufacture to perform specialized engineering calculations at a cost that is many times less than a Flight Specialist or real-life Engineer.

Module 1 – TruBlank™ Flight Blank Designer calculates an instantaneous accurate cutting size for the flat helical flight blank. The results are displayed graphically and can be saved as a DXF file for transfer.

Module 2 – TruTool™ Machine Configuration Tool evaluates the individual mechanical characteristics of the required material to select the appropriate tool set and the exact tool set up.

2. AST’s TruForm™ Flight Forming Tools removes the need for size specific, shaped tooling and can be precisely set to suit every individual parameter of your helical screw flight regardless of its complexity.

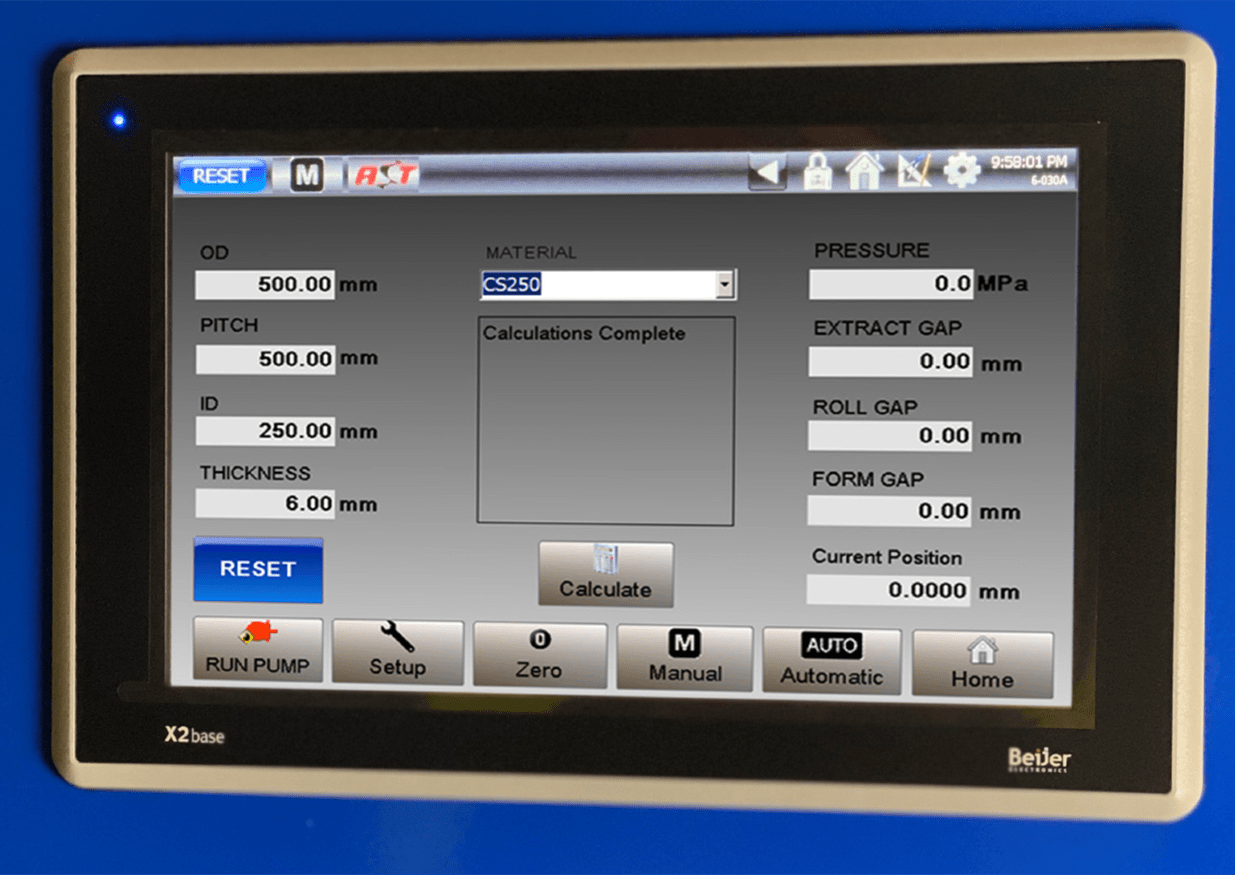

3. AST’s TruSet™ Forming Parameters Program assists any operator to swiftly accumulate the skills to efficiently form accurate helical screw flights allowing a novice to become competently to train in sectional helical screw flight manufacturing within days.

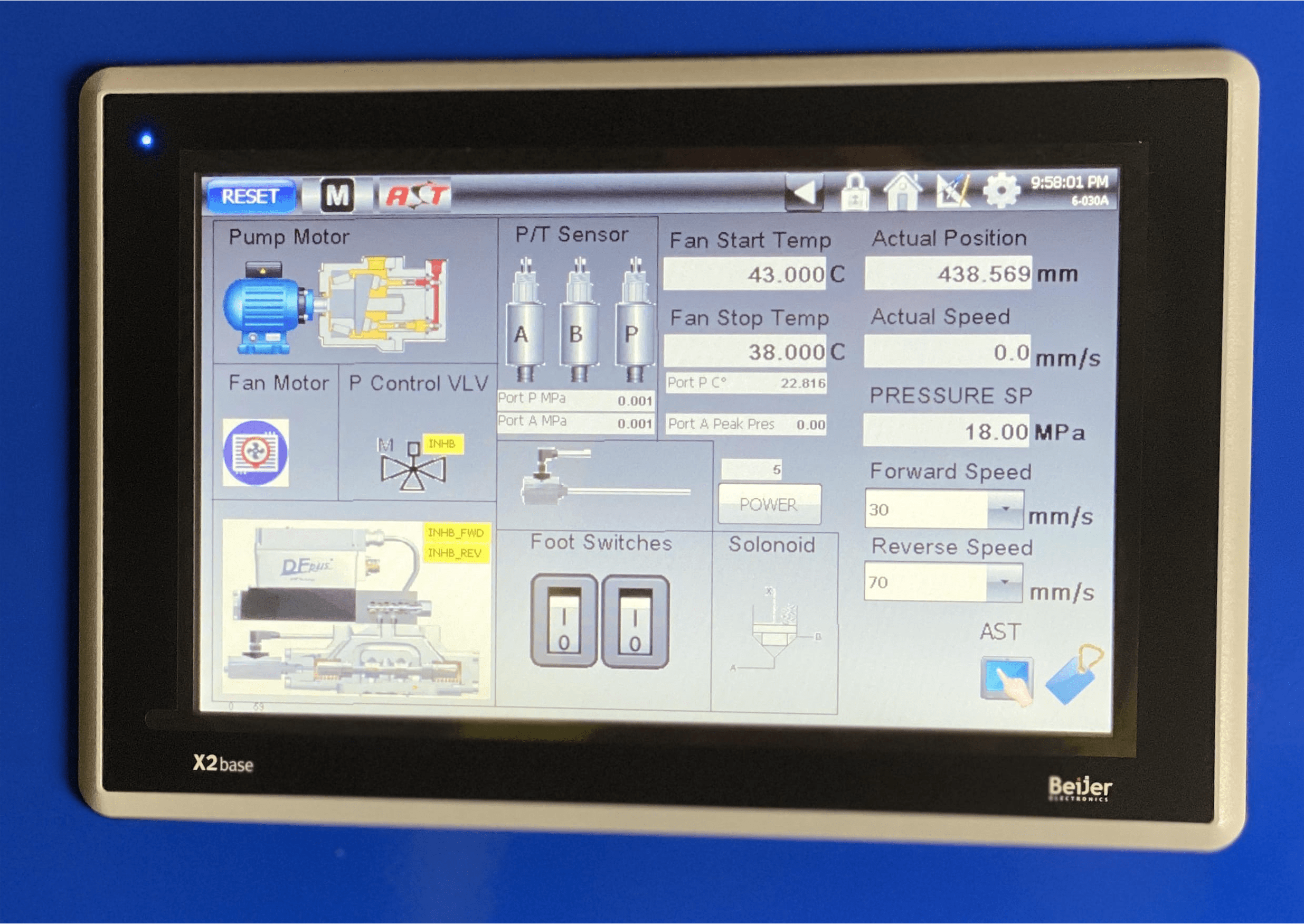

With the TruHelix™ software suite, you simply input the finished helix flight parameters of Outside Diameter, Inside Diameter, Pitch, Thickness, and Material, and your TruPress™ helical screw flight-forming machine will automatically set the speed, pressure, and travel set points applicable to the helical screw flight to be formed.