Why Nothing Compares to AST’s Premiere Helical Flight Forming System

Dec 05, 2018

TruHelix™ – The Genuine Flight Forming System – Nothing Compares

Today, there are many organisations around the world that claim to have a Helical Screw Flight Manufacturing System that lifts the cloak on the “Black Art” that is sectional screw flight forming. Some claim to have technology that is the equivalent of AST, however, they have realistically done nothing more than dress up existing methods and techniques, and some have attempted to copy our revolutionary technology yet do not understand how it works!

All are missing the most vital elements that differentiates our system from others.

These critical components are necessary if you wish to truly eliminate the reliance on an “expert” flight former and manufacture flights with a true helix.

Without the combined functions of our TruTool™ Machine Configuration Tool Program, TruPress™ Flight Forming Machine and TruForm™ Forming Plates you will at some stage end up still being beholden to a self-proclaimed “expert” that is needed to apply their unique finesse to achieve an acceptable finished flight helix.

AST Operative/Users have eliminated the reliance on the operator’s experience and skill allowing them to train a novice to become competent at sectional helical screw flight manufacturing within days, NOT months and years.

AST’s TruFlight™ Software Suite – The intelligence

TruFlight™ Software Suite: The software component of our TruHelix™ Flight Forming System has taken the secretive, and highly guarded, IP of sectional screw flight helical manufacture, that is intentionally kept locked in the head/s of the extremely scarce “Flight Expert/s”, and placed it into the possession of the many, making the need for the essential “Flight Expert” practically redundant.

Our TruFlight™ Software Suite incorporates two unique programs that perform specialised engineering calculations at a cost that is many times less than a Flight Specialist or real-life degree qualified Engineer.

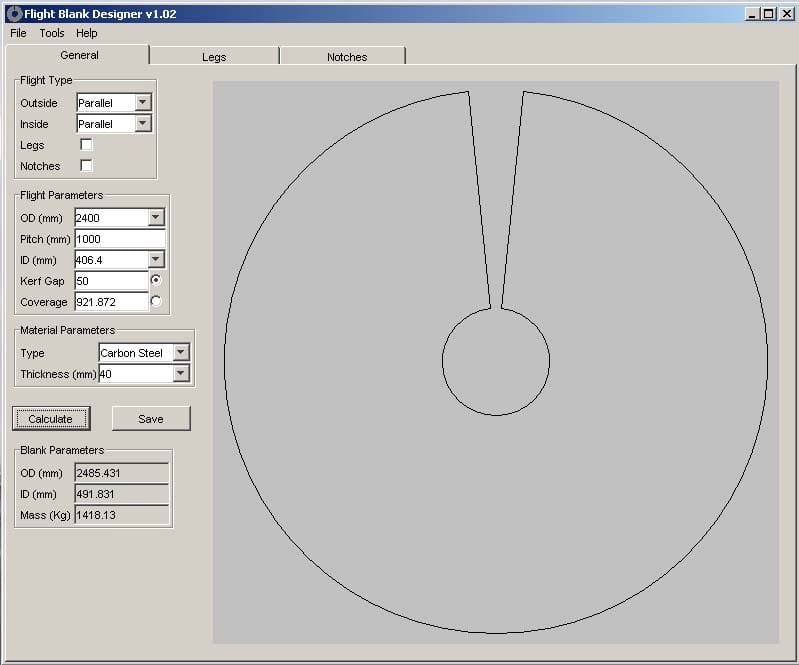

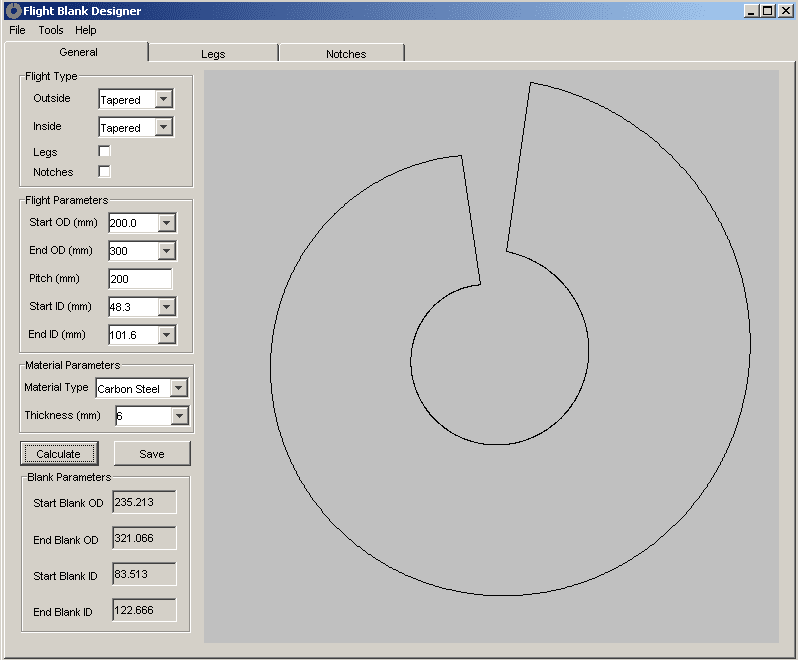

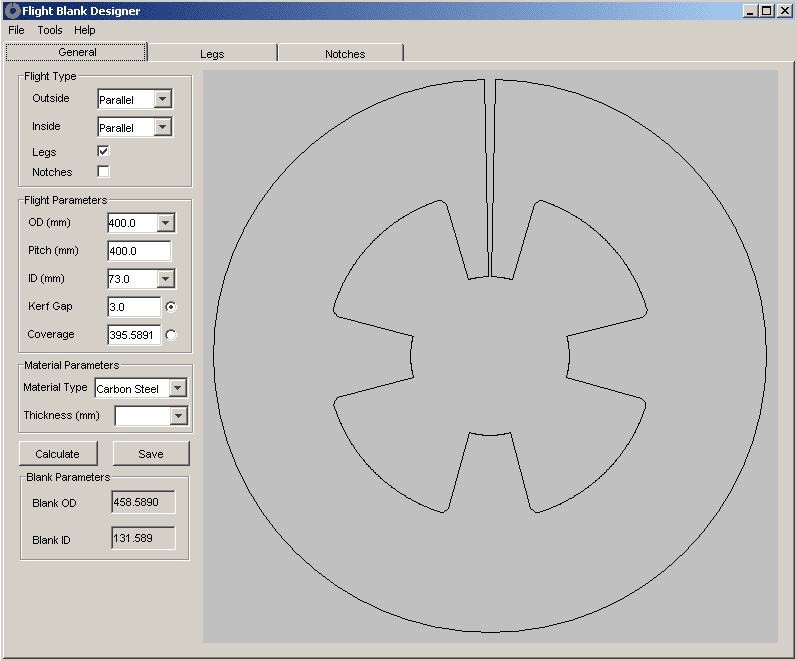

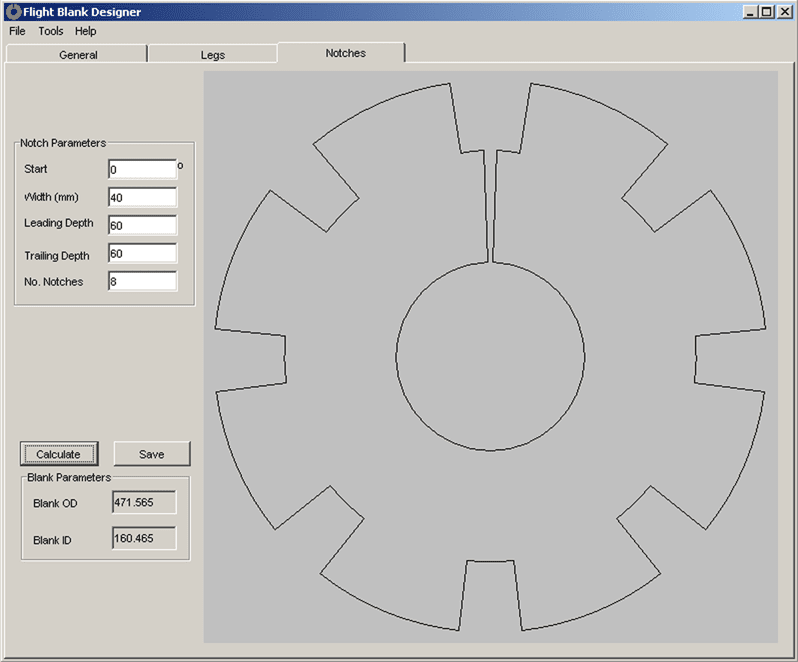

Program 1 – TruBlank™ Flight Blank Designer (incorporating the Combination Flight Tool)

An integral component to any sectional screw flight helix forming system is the accurate calculation of the helical flight blank. Our TruBlank™ Flight Blank Designer Program allows you to input your finished flight helix parameters:

- Outside diameter – standard or tapered.

- Inside diameter – standard or tapered.

- Pitch

- Material Thickness.

- Material Type

- Additional Features – Legs, Notches, Holes, Windows & Cant Angle

The cutting size for the flat helical flight blank will be instantaneously calculated. The results are displayed graphically on the screen and can be saved as a DXF file to transfer to your cutting machine.

TruBlank™ Flight Blank Designer Program

Program 2 – TruTool™ Machine Configuration Tool Program

AST has, as part of the “system”, developed and made available to their Operative/Users the software program we refer to as TruToolä. The inputs to this program are:

- Outside diameter.

- Inside diameter.

- Pitch.

- Material Thickness.

- Material Type.

The program is preloaded with most common material types, however new materials can be added at any time. Built into the program is Young’s Modulus, 0.2% Proof Stress (Yield Strength for mild steel) and the materials Proportionality Limits.

This provides a computation that scientifically considers “spring back”. Subsequently, the program will select the correct forming plates, from the database of available plates, making allowance for the varying “spring back” associated with materials of different strengths. The program also calculates the exact position of the forming plates and the helical flight blank support bars and displays a set up procedure that can be printed out (with the scope of work) and given to the machine operator to set the forming plates correctly in the machine.

Our TruFlight™ Software Suite is the intelligence behind our TruHelix Flight System as it provides a Virtual Engineer at your fingertips for the fraction of the cost of an actual in-house degree qualified expert.

AST’s TruPress™ Flight Forming Machines – The skills

AST’s TruPress™ Flight Forming Machines are numerically controlled, semi-automatic sectional screw flight helix forming machines that come complete with our revolutionary TruSetä Forming Parameters Program preloaded and pre-calibrated. AST’s TruSet™ enabled TruPress™ Flight Forming Machines are the only machines on the market with the experience and skill built in.

Every AST’s TruPress™ Flight Forming Machine comes complete with our TruSet™ Forming Parameters Program, preloaded and factory calibrated, providing the operator with the ability to set the machine to the correct outputs ensuring consistent outcomes all of the time, every time, resulting in superior high-volume productivity. The operator need simply key into the control panel the finished flight parameters of Outside Diameter, Inside Diameter, Pitch, Thickness and Material and your flight forming machine will automatically set the speed, pressure and travel set points applicable to the flight to be formed.

AST’s TruForm™ Flight Forming Tools – The precision

AST’s ambidextrous TruForm™ Forming Plate Sets have revolutionized the forming of Sectional Screw Flight Helices making the old generation technology of heavy, high wear, specific shaped tooling redundant.

TruForm™ interchangeable, specially hardened Forming Plates produce a flight helix of unprecedented quality regardless of the Pitch, Outside Diameter, Inside Diameter, Material or Feature.

The same set of TruForm™ Forming Plates can produce both Right Hand and Left Hand Helical Screw Flights and because of their specially hardened design wear and maintenance is negligible. TruFormä

Forming Plates can be changed by hand in a matter of minutes and inventory requires a relatively small space, compared to the enormous stock of shaped dies (right and left hand) required for “traditional” helical screw flight forming.

Super Tyro – IP TruPress™ Flight Forming Machine

Since its launch, back in 2010, the SuperTyro™ forming press quickly established itself as our most popular and versatile TruPress™ model.

The “specific for purpose” design of AST’s SuperTyro™ – IP TruPress™ Flight Forming Machine has produced a robust piece of equipment with market leading reliability and durability.

Whether the machine is used for a few hours a day or 24/7/365, a properly maintained SuperTyro™ is built to run for decades.

In today’s workplace, occupational health and safety is an extremely important prerequisite for all responsible employers, and their employees, so AST considered carefully, the design and construction of the SuperTyro™ to ensure that the highest safety standards (CE) and thoughtful ergonomics were built in.

Combining the SuperTyro™’s capabilities with our TruFlight™ Software Suite Operative/Users now have the advantage of being able to consistently form the vast majority of the world market’s sectional helical screw flight needs accurately and efficiently, without any reliance on a “Flight Specialist”.

With close to sixty (60) machines operating on six (6) continents, in more than twenty (20) countries the SuperTyro™ has proven itself to be the premier Helical Screw Flight Forming Machine on the market.

It is testament to the recognised advantages of AST’s SuperTyro™ when the world’s largest and most reputable Sectional Screw Flight Helix Manufacturers are enhancing their existing Flight Forming Production with AST’s SuperTyro™ – IP TruPress™ Flight Forming Machine.